Stampante 3D per metallo Figure 4 135industriale

Aggiungi ai preferiti

Confronta con altri prodotti

Vuoi acquistare direttamente?

Vai sul nostro Shop.

Caratteristiche

- Materiali stampati

- per metallo

- Applicazioni

- industriale

Descrizione

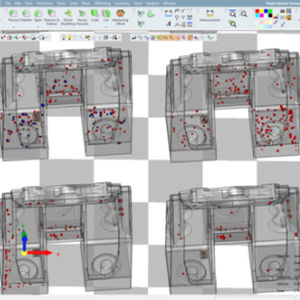

High-speed, high-precision 3D printing solution When you need to supplement or replace injection molding tools in plastic production, Figure 4 135 enables faster, more flexible, and cost-effective production for both prototyping and low-to-medium volume end-use parts. By directly producing small plastic end-use parts, the solution eliminates weeks or months of mold lead times, reducing time-to-market from weeks to days. Engineers can quickly prototype and iterate designs on the fly without retooling. The solution allows companies to produce with the highest level of accuracy and repeatability, whether for prototypes, small batches, custom parts, bridge production, or on-demand spare parts—all without the overhead of tooling costs or inventory management. Speed: The fastest 3D printing technology; projectors rapidly cure layers whether building a single small part or a full platform of many parts. Accuracy and Repeatability: High-power projector and image processing IP deliver ready-to-use accuracy and repeatability from part to part and printer to printer. Production Ready: Hands-free automatic door for easy access to the print area by operator or robot. Onboard production traceability features. Self-feeding resin tray from a high-capacity cartridge. Ease of Use: Simple to use and maintain to maximize uptime. Automated functions and preset profiles speed up and standardize procedures for easy management of a printer fleet. Printer Overview Figure 4 135 combines accurate, high-power light projection printing with IP image processing for extremely precise and repeatable parts. Industrial features like the automatic door and high-volume resin cartridge auto-fill enable more efficient workflows and reduce operator intervention. New traceability and fleet management features give you total control over processes. Developed in compliance with the latest cybersecurity standards for operational safety. Materials: Figure 4 resins – see Material Finder. Includes a diverse set of specialty, durable, tough, and rigid materials; the widest selection of flame-retardant (FR) materials; high-temperature and elastomeric materials. High-Performance Resins Designed to work with the Figure 4 range of engineering-grade, high-performance resins, achieving printed parts with injection-molding-like quality and best-in-class smooth finish. Choose from a growing range of rigid, tough, durable, thermoplastic-like, castable, heat-resistant, and biocompatible materials in a wide range of colors and translucencies. Printed parts have long-term mechanical properties resistant to UV and humidity; up to 8 years for indoor use and up to 1.5 years for outdoor use (tested per ASTM D4329 and ASTM G194). New Hardware Architecture Powerful Light Source: High-power QHD projector with dynamic adjustments and pixel control for repeatable maximum accuracy and long-term performance. Material Loading: Built-in flexibility to automatically pump resin from a 9 kg high-capacity cartridge or pour manually for low-volume printing or material testing. Clean Interior: Designed for easy, fast maintenance; all surfaces are flat, seamless, and stainless materials are tested for tough cleaning conditions. Adjustable Screen: 7-inch touchscreen user interface adjusts angle for glare-free visibility; easy to see for quick task completion. Automatic Door: Choice of pedal or user interface for automatic door opening/closing saves time, reduces labor, increases throughput, and enables future-proof automation integration. New Software Architecture Traceability Features: Track build platforms and parts; easily track machine ID, material lot numbers, and production date/time. Fleet Management: Manage an entire printer fleet from a PC or laptop. Intelligent queue management based on material availability and print start time control. Touch User Interface: HD multi-touch screen displays information clearly and enables faster task completion. Adjustable Screen: 7-inch touchscreen user interface adjusts angle for glare-free visibility; easy to see for quick task completion. Flexible Production Figure 4 135 delivers batch-level results, the true quality needed to supplement traditional manufacturing operations. With extremely high accuracy from the start, Figure 4 135 is ideal for manufacturing industries where a process capability index (CpK) of at least 1.33 or higher* is required for critical processes. The printer significantly exceeds these standards, making it highly reliable for precision applications. Whether building small quantities for design iteration or filling a platform with large quantities of small components, performance and output remain consistent and repeatable across multiple printers. Part Quality Produces parts of exceptional quality and accuracy, a direct result of proprietary pixel fusion methods combined with precision projectors and innovative hardware configuration. All materials, print processes, image processing software, and printer hardware are the result of over 15 years of pixel printing experience by 3D Systems, ensuring seamless integration. The image processing software automatically adjusts pixel edges with grayscale scaling techniques, enabling high-quality, high-performance plastic parts with best-in-class surface quality. Figure 4 Technology Uses projector-based imaging and non-contact membrane technology to rapidly build complex, high-resolution parts. Instead of a laser as in traditional stereolithography (SLA), Figure 4 uses an array of projectors to cure an entire layer of liquid resin at once. This enables high print speeds and high-resolution prints. The higher-resolution projector improves accuracy and precision, enabling fine details and thin walls needed for connectors. Cure 400 Cure 400 is a medium-sized curing oven with advanced features, offering scalable options for post-processing UV-curable resins. Equipped with a rotating table for reduced part shadowing, full-spectrum LEDs, and a curing volume of 400 x 400 x 400 mm. Compatible with all 3D Systems UV photopolymers for durable post-processing and optimal material properties. Preprogrammed selectable recipes save time and operator training. Compatible with parts from all Figure 4, PSLA, and SLA printers (if parts fit the oven volume). 3D Sprint Software Single software application from CAD model to print Optimized data management for efficiency Simplifies print times and finished parts with a single, easy-to-use interface Improves productivity and reduces printer downtime with management and monitoring tools Applications Direct production of small plastic end-use parts Flame-retardant (FR) parts for electronics and connectors Thin-walled components Prototyping and testing Housings, covers, and snap-fit elements Sensors Knobs, washers, and spacers Advantages Fastest printing technology High throughput and multiple builds per day Accuracy and repeatability, part-to-part and printer-to-printer Batch and series production Advanced workflow tools for managing one or a fleet of printers Easy and quick material replacement Automated hands-free door Industrial-grade durability Material flexibility for high-performance production Technical Specifications Printable build area (xyz): 136 x 76 x 165 mm (5.3 x 3.0 x 6.5 in) Resolution: pixel size 50 μm Projector resolution: 2716 x 1528 Control panel: 7" HD display with multi-touch screen Dimensions (W x D x H): 680 x 700 x 1360 mm (26.8 x 27.6 x 53.6 in) Weight: 76 kg (167.5 lbs) Power supply: 100 - 240 VAC, 50/60 Hz, single phase, 5 A Operating humidity: 30-70% relative humidity Software: 3D Sprint for print preparation and monitoring Production Efficiency and Cost Savings Integrating traditional small plastic part production with Figure 4 135 unlocks additional efficiencies and cost savings. While injection molding tools are best for high volumes, other factors such as long lead times, high initial investment, and costly design changes must be considered. Once a tool is used, it must be inventoried, stored, and maintained. In contrast, a Figure 4 135 printer can be used for prototyping, product development, and bridge production with no limits on the number of possible SKUs. Hundreds of thousands or millions of dollars can be saved by supplementing traditional manufacturing with the Figure 4 135 solution. Validated Materials Include: Figure 4 Tough 75C FR, Figure 4 FLEX-BLK 20, Figure 4 Tough FR V0 Black, Figure 4 Rigid White, Figure 4 Hi Temp 150C FR BLK, Figure 4 Rigid Gray, Figure 4 PRO-BLK 10, Figure 4 EGGSHELL AMB-10, Figure 4 HI TEMP 300-AMB Key Features: High-speed, high-precision 3D printing, hands-free automatic door, advanced traceability, fleet management, wide range of engineering-grade resins, industrial durability, easy maintenance, and advanced software integration. Technical Specifications: Printable build area: 136 x 76 x 165 mm Resolution: 50 μm pixel size Projector resolution: 2716 x 1528 Control panel: 7" HD multi-touch Dimensions: 680 x 700 x 1360 mm Weight: 76 kg Power: 100-240 VAC, 50/60 Hz, single phase, 5 A Operating humidity: 30-70% RH Software: 3D Sprint

Cataloghi

Nessun catalogo è disponibile per questo prodotto.

Vedi tutti i cataloghi di 3D SystemsFiere

Fiere a cui parteciperà questo venditore

Ricerche correlate

- Stampante 3D 3D Systems

- Stampante 3D industriale 3D Systems

- Stampante 3D per materie plastiche 3D Systems

- Macchina di prototipazione rapida 3D Systems

- Stampante 3D ad alto rendimento 3D Systems

- Stampante 3D ad alta velocità

- Stampante 3D per metallo 3D Systems

- Stampante 3D ABS

- Stampante 3D grande formato

- Stampante 3D PLA

- Stampante 3D medico

- Stampante 3D odontoiatrico

- Stampante 3D di resina

- Stampante 3D in poliammide

- Stampante 3D PETG

- Stampante 3D per il settore aerospaziale

- Stampante 3D SLA 3D Systems

- Stampante 3D per l'industria automobilistica

- Stampante 3D in nylon

- Stampante 3D SLS

* I prezzi non includono tasse, spese di consegna, dazi doganali, né eventuali costi d'installazione o di attivazione. I prezzi vengono proposti a titolo indicativo e possono subire modifiche in base al Paese, al prezzo stesso delle materie prime e al tasso di cambio.