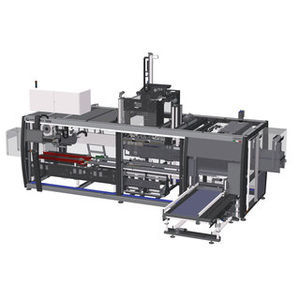

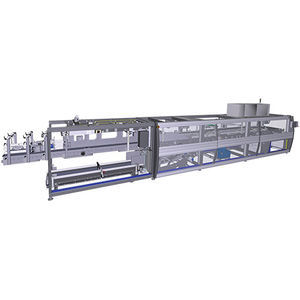

Incartonatrice avvolgitrice WP 1000 ERGONa carico dall'altoper l'industria cosmeticaper l'industria agroalimentare

Aggiungi ai preferiti

Confronta con altri prodotti

Vuoi acquistare direttamente?

Vai sul nostro Shop.

Caratteristiche

- Tipo

- a carico dall'alto, avvolgitrice

- Applicazioni

- per l'industria farmaceutica, per l'industria agroalimentare, per l'industria cosmetica

- Altre caratteristiche

- automatica

- Cadenza

100 p/min

Descrizione

The WP ERGON series consists of automatic machines for packaging plastic, metal, cardboard, or glass containers in corrugated cardboard boxes and/or trays without film at speeds of up to 100 packs per minute, depending on the chosen model and product type.The formats that can be produced vary according to the shape, capacity, and size of the containers; generally, the most requested configurations on the market are: 2x3, 3x4, and 4x6.The new WP 1000 ERGON stands out for its innovative automatic guide adjustment system, located at the machine's entrance, which significantly reduces downtime and ensures consistent quality and efficiency during format changes.The case packer is also equipped with a top product separation system, ensuring high operational efficiency.The grouping of products occurs smoothly, quickly, and reliably, thanks to two opposing bars that release the products according to the selected format.Format changes are equally simplified: operators simply remove the plates with separation pins from the upper bars and replace them with those suitable for the new format.WP 1000Speed (PPM)100Pack typeTray onlyWrap-around boxLanes1Main features:Supporting structure in sandblasted and powder-coated steelSliding protective doors in anodized aluminum with rounded shape, allowing all (low energy consumption) motors to be positioned outside the mechanical groups they drive. The door closing system is equipped with a deceleration device, which slows down the final phase of the run, harmoniously accompanying the door.Absence of gearmotors and predominant use of ICOS brushless motors with integrated digital servo drive (driver)Continuous product grouping device, with electronically synchronized plastic combsLifetime lubricated bearingsInfeed conveyor with low-friction thermoplastic chains and motorized oscillating channeling guidesCarton magazine located under the infeed conveyor, in an easily accessible position (models P and T)Cam carton feeder equipped with vacuum suction cup systemMachine electrical cabinet equipped with air conditionerInteractive touchscreen with intuitive graphicsOperation:On the machine's infeed conveyor, equipped with low-friction thermoplastic chains, a special group of motorized oscillating guides correctly channels the loose containers towards the pack formation area, where the containers are continuously grouped in the selected format by electronically synchronized pins.The new Easy-Load system automatically loads the cardboard blanks into the machine's dedicated carton magazine. The new loading device consists of a series of motorized belt conveyors on which the operator easily places the cardboard blanks in uniform horizontal stacks.A corrugated cardboard blank is picked up from the magazine by a newly designed feeder equipped with vacuum suction cups, travels up the carton ramp, and is positioned under the incoming product group with the short side facing forward. The box/tray former operates continuously with a wrap-around system.Subsequently, the flap folding devices fold the side flaps first and then the upper/lower flaps of both the front and rear. Hot glue closure ensures excellent pack sealing.At the machine's exit, the pack walls are kept pressed by special guides.Advantages:Modular design: SMI machines are designed according to advanced modular assembly principles and interchangeability of mechanical and electronic components, minimizing production downtime during technical assistance or scheduled maintenance and optimizing spare parts management.Operational flexibility: These packers allow packaging a wide range of products in many different configurations, effectively responding to the changing needs of the end user. Each machine can also be equipped with additional equipment to increase its basic functions and ensure a high level of customization of the final pack.Motors connected in line: SMI machines are built without gearmotors; the motors are directly connected to the transmission shafts, reducing maintenance, energy dissipation, and noise.Continuous pack formation: The continuous packaging system ensures a smooth production process, without jerky movements; it also protects containers from impacts, ensuring greater reliability, better pack quality, and reduced mechanical wear.Thermoplastic separation pins: In the pack formation area, the use of thermoplastic separation pins, which last longer than metal ones, reduces machine noise and preserves the integrity of more delicate containers (such as glass) and labels.Easy and economical maintenance: The rounded protective doors allow more space inside the machine and thus have the motors mounted outside the mechanical groups they drive, making it easier for the operator to perform all activities related to the use and maintenance of the system.Innovative shapes: All SMI case packers can produce hexagonal or octagonal boxes made of microflute/miniflute corrugated cardboard, which can undergo more sophisticated graphic printing processes than standard corrugated cardboard.Perfect box formation: SMI case packers are equipped with fixed guides that keep the pack walls pressed at the machine's exit. This system ensures perfect and lasting squaring of the boxes, unlike rotating chain pressing systems that cannot provide the same quality level.User-friendly control system: The POSYC® control panel, sliding on a rail along the entire length of the machine, allows even less experienced operators to use the packer easily and efficiently. This is possible thanks to the extremely intuitive graphical interface, the touch screen, and the advanced diagnostic and real-time technical support functions present on POSYC®.Accessories:Easy-Load: The innovative "Easy-Load" system allows automatic loading of the carton magazine and offers significant operational and functional advantages; the cardboard blanks, stacked horizontally in uniform groups, can be easily loaded by the operator, as the magazine's feed belt is at the same working height as the packer's infeed conveyor, instead of below it. The patented system consists of a series of motorized belt conveyors dedicated to feeding the packer's carton magazine; on these belts, the stacks of cardboard blanks advance to a transfer area and then to the collection system at the entrance of the case packer or shrink wrapper. Thanks to special sensors, the arrangement and advancement of the cartons on the motorized belts and their loading into the actual magazine of the packer is fully automated. The technology used in the "Easy-Load" magazine also ensures smooth and constant feeding operations with a wide range of cardboard blanks with thicknesses between 0.5 mm and 5 mm.PID SBP®: Allows the insertion of pre-assembled solid board separators inside cardboard boxes to protect particularly delicate products (such as glass containers) from damage or breakage and preserve labels from possible abrasions. This device can be installed on WP wrap-around case packers and combined CM machines. Compared to the traditional method of inserting non-assembled corrugated cardboard separators, the PID SBP® allows: reducing the purchase cost of separators by about 20% and storage volume by at least 60%; maintaining the same footprint as a standard case packer, as both the separator magazine and the insertion device are mounted on top of the packaging machine; speeding up the separator insertion and magazine loading process, as these are already pre-assembled; decreasing the sensitivity of separators to humidity and climate changes. The PID SBP® and its pre-assembled separator magazine are positioned at the machine's entrance, above the pack formation area. The maximum operating speed is 40 packs per minute (1-head model) or 60 packs per minute (2-head model). A mechanical arm with vacuum suction cups picks up a pre-assembled separator from the magazine, opens it, and deposits it from above between the underlying containers before they are grouped in the desired configuration. In the final phase, a cardboard blank from the magazine is wrapped around the products by special guides to form a closed box.Technical specifications:Supporting structure in sandblasted and powder-coated steelSliding protective doors in anodized aluminum with rounded shapeAbsence of gearmotors, use of ICOS brushless motors with integrated digital servo driveContinuous product grouping device with electronically synchronized plastic combsLifetime lubricated bearingsInfeed conveyor with low-friction thermoplastic chains and motorized oscillating channeling guidesCarton magazine under the infeed conveyor, easily accessible (models P and T)Cam carton feeder with vacuum suction cup systemMachine electrical cabinet with air conditionerInteractive touchscreen with intuitive graphics

Cataloghi

Nessun catalogo è disponibile per questo prodotto.

Vedi tutti i cataloghi di SMI GroupFiere

Fiere a cui parteciperà questo venditore

Ricerche correlate

- Macchina di confezionamento

- Macchina di riempimento automatica

- Macchina di confezionamento automatica

- Riempitrice per liquido

- Macchina per imballaggio per l'industria agroalimentare

- Pallettizzatore

- Macchina di riempimento volumetrica

- Fardellatrice SMI

- Fardellatrice automatica SMI

- Linea di imballaggio

- Pallettizzatore automatizzato

- Incassatrice SMI

- Incassatrice automatica SMI

- Pallettizzatore robotizzato

- Linea di imballaggio automatica

- Macchina per imballaggio per l'industria farmaceutica

- Macchina di riempimento compatta

- Incartonatrice

- Macchina per imballaggio ad alta velocità

- Pallettizzatore per casse

* I prezzi non includono tasse, spese di consegna, dazi doganali, né eventuali costi d'installazione o di attivazione. I prezzi vengono proposti a titolo indicativo e possono subire modifiche in base al Paese, al prezzo stesso delle materie prime e al tasso di cambio.